|

In order for a filter press to function properly the selection of a feed pump is very important. Hiperk recommends the use of three different styles:

● 1.Air Diaphragm pumps

● 2.Centrifugal pumps

● 3.Progressive cavity pumps

The pump must be capable producing the calculated flow at the maximum pressure for which the press is rated (typically100 psi (7.5bar) or 225psi (16bar). This flow and presure must be able to be controlled pneumatically or electrically to gradually build up a filter cake in the filter chamber. The pump must also be rated to handle large solids, heavy slurries and abrasive solids.

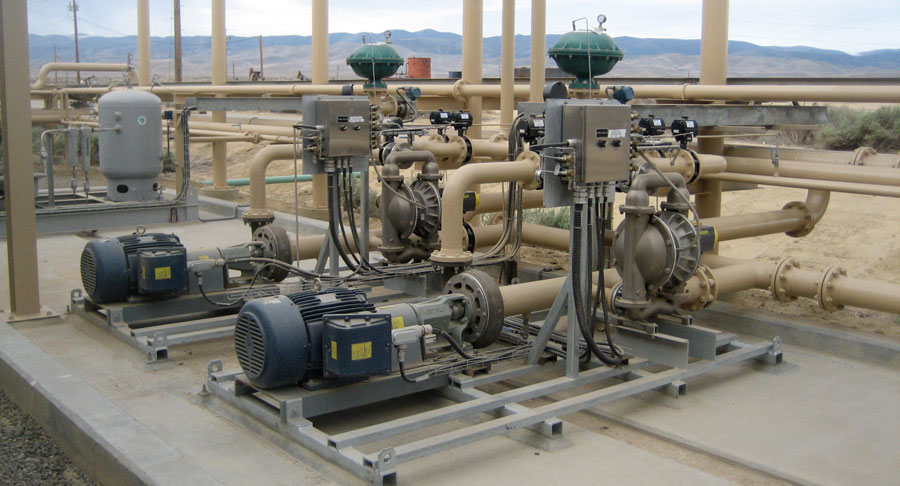

Air Diaphragm Pumps

Air diaphragm pumps are ideal for feeding heavy sludges into filter presses. This low cost, simple to maintain pump uses compressed air to operate and can be provided with an incremental pressure controller to form a dryer cake.

Air diaphragm pumps are designed to operate by compressed air and are capable of pumping heavy sluries. The main advantageis that an air diaphragm pump can be in a "stall" condition and not "burn up". This stall feature is used to compact solids firmly into the filter chamber. The addition of a pump controller enables this stall time to be programmed as a feature in an Automatic Pump Controller or AP-3.

|